Imagine this all-too-common scenario: your multi-million-dollar project is deep into the construction phase. Structural steel is erected, and large equipment is in place. Then, the piping team arrives on-site only to discover that their pre-fabricated spool runs directly through a primary support beam. The work grinds to a halt. The blame game begins. The project faces costly rework, schedule delays, and a cascade of logistical nightmares.

This is a “hard clash,” and for decades, it has been a persistent plague on complex industrial projects. Traditionally reliant on 2D drawings, engineers and designers did their best to coordinate, but human error and the sheer complexity of modern facilities made clashes inevitable.

Today, however, there is a powerful solution: 3D modeling and automated clash detection. This technology has revolutionized plant design, transforming it from a process of prevention and hope into one of precision and certainty.

Beyond the Blueprint: The Limitations of 2D Drawings

For years, 2D drawings (plans, elevations, sections) were the industry standard. While effective, they have inherent limitations. They require each discipline—civil, structural, mechanical, electrical, and piping—to mentally visualize how their individual 2D components fit together in a 3D space. This manual process is prone to misinterpretation and oversight, making it nearly impossible to identify every potential conflict before construction begins.

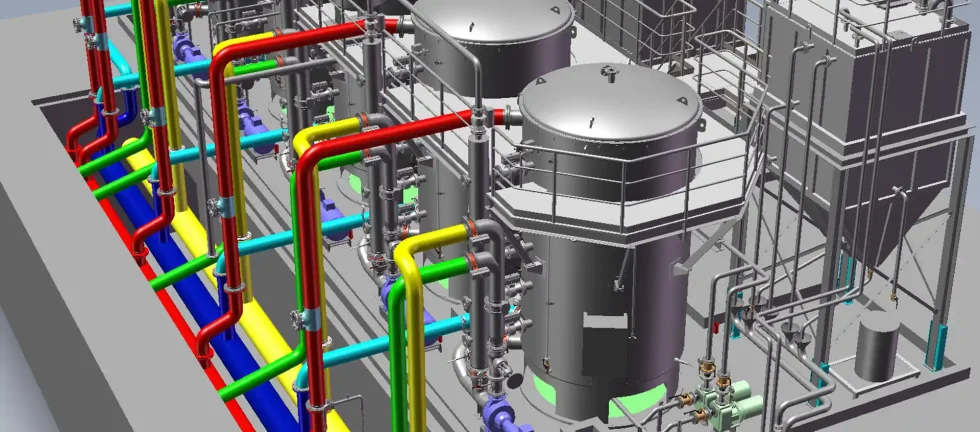

The Power of a Digital Twin: 3D Modeling and BIM

3D modeling moves beyond flat representations to create a comprehensive, data-rich digital twin of the entire facility before a single piece of steel is ordered. Using advanced software like AutoCAD Plant 3D, AVEVA E3D, or Intergraph Smart 3D, engineers build an intelligent virtual model where every component—from pipes and valves to cable trays and HVAC ducts—exists in its precise location.

This process is a cornerstone of Building Information Modeling (BIM), an integrated approach where the 3D model becomes a central source of truth for all project stakeholders, from designers to fabricators and construction teams.

The Core Benefit: Automated Clash Detection

The true magic happens when these individual discipline models are combined into a single, federated model. Specialized software like Navisworks can then run an automated analysis, meticulously checking the entire facility for geometric interferences. This process identifies hundreds or even thousands of potential issues that would be impossible to catch manually.

Clashes are typically categorized into three types:

- Hard Clashes: This is the classic example of two solid objects occupying the same space, like a pipe running through a steel column. These are the most expensive and disruptive clashes to fix on-site.

- Soft / Clearance Clashes: This occurs when an object doesn’t have the required spatial clearance for maintenance, safety, or operation. For example, a valve placed too close to a wall, preventing an operator from turning it, or equipment blocking a critical escape route.

- Workflow Clashes: This refers to timeline and sequencing conflicts, such as scheduling drywall installation before electrical wiring is complete. Advanced BIM processes can help identify these as well.

Tangible Benefits of Integrating 3D Modeling

By identifying and resolving these clashes in the digital phase, projects realize enormous benefits:

- Drastically Reduced Rework: Fixing a clash on a computer screen costs virtually nothing. Fixing it in the field can cost tens of thousands of dollars in labor and materials.

- Improved Project Schedules: By eliminating on-site surprises, construction can proceed smoothly and predictably, minimizing delays.

- Enhanced Safety: A well-coordinated design ensures safe access, proper clearances for equipment operation, and clear escape routes.

- Accurate Material Take-Offs: The 3D model can generate highly accurate bills of materials, reducing waste and improving procurement accuracy.

- Better Collaboration: The visual nature of the model allows all stakeholders, including non-engineers, to understand the design, leading to better communication and decision-making.

At Provenex Engineering, 3D modeling and clash detection are standard practice. We leverage cutting-edge technology to provide our clients with a clear, accurate, and clash-free design package. Our expertise ensures that what you see on the screen is exactly what gets built on-site—efficiently, safely, and on budget.

Ready to build with confidence and eliminate costly surprises? Contact Provenex today to learn how our advanced 3D modeling services can de-risk your next project.

Comments (2)

Riva Collins

It’s no secret that the digital industry is booming. From exciting startups to need ghor

global and brands, companies are reaching out.

Oliva Jonson

It’s no secret that the digital industry is booming. From exciting startups to need ghor

global and brands, companies are reaching out.